Chamber sealers create a sealed environment inside the chamber, allowing you to remove all air more thoroughly for stronger, longer-lasting seals. Unlike external models that seal around the outside, these machines offer consistent results, ideal for food preservation, bulk packaging, and delicate items. They also support better preservation with enhanced vacuum power and even heat application. If you want to master professional-quality sealing, there’s more to discover about how they work and choose the right one.

Key Takeaways

- Chamber sealers create a sealed environment inside the chamber, ensuring consistent and high-quality vacuum and sealing results.

- They remove more air and deliver stronger, more reliable seals compared to external vacuum sealers.

- Integrated vacuum and heat functions allow for simultaneous operation, optimizing preservation of delicate or liquid items.

- Chamber sealers support larger volumes and professional-grade packaging, ideal for commercial or serious home use.

- Regular maintenance of seals, gaskets, and components is essential to sustain performance and sealing quality like a professional.

What Are Chamber Sealers, and Why Are They Better Than External Models?

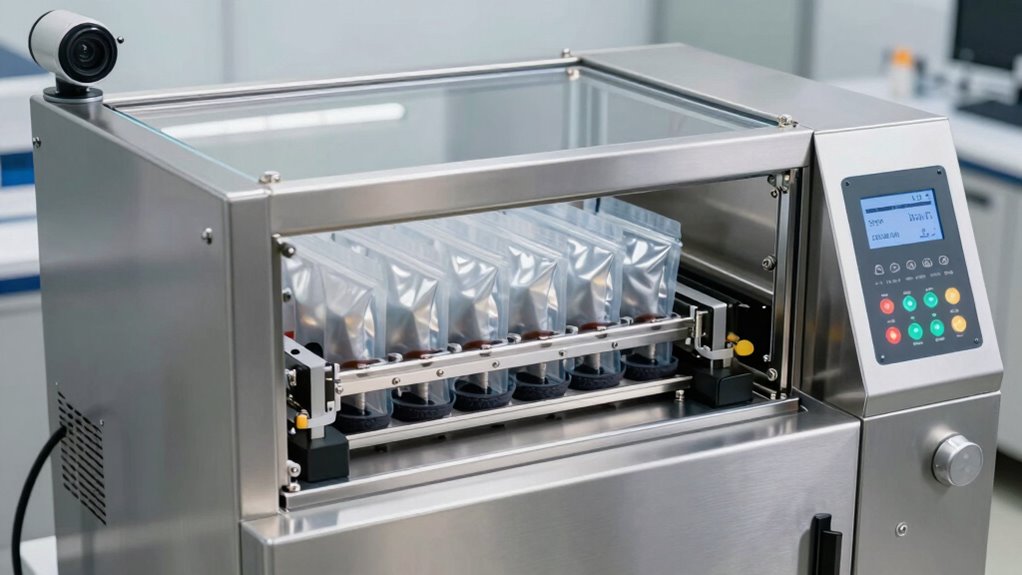

Chamber sealers are specialized vacuum packaging machines that create a sealed environment around the bag inside the chamber itself. This design offers advantages over external models, especially regarding consistent sealing quality. When considering maintenance tips, chamber sealers require regular cleaning of the chamber and seals to prevent debris buildup, ensuring peak performance. They also tend to have higher upfront costs, but a clear cost comparison shows they’re more economical over time due to durability and efficiency. External models often need replacement bags and filters more frequently, increasing ongoing expenses. Additionally, choosing energy-efficient chamber sealers can contribute to more sustainable packaging practices and reduce operational costs. Incorporating proper calibration ensures optimal sealing performance and prolongs the lifespan of the machine. Regular maintenance practices are essential to keep the chamber sealers operating at peak performance, preventing costly downtime. Proper storage techniques can also extend the lifespan of the vacuum bags and protect the machine’s components. Overall, chamber sealers deliver a reliable, professional-grade seal, making them ideal for bulk packaging needs, despite their initial investment. Their long-term savings and superior performance make them a smart choice.

What Are the Main Benefits of Using Chamber Sealers for Food and Bulk Packaging?

Using chamber sealers gives you better air removal, ensuring your food stays fresh longer. Their superior seal strength keeps packages secure, preventing leaks or spoilage. These benefits make chamber sealers a smart choice for preserving both food and bulk items efficiently. Additionally, their ergonomics and workflow features can streamline your packaging process, making it more comfortable and efficient for everyday use. The precise sealing process helps maintain optimal freshness and reduces waste over time. Incorporating advanced technology and design features can further enhance sealing performance and user experience. Being aware of seal integrity is crucial to ensure your packaging remains reliable over multiple uses, especially as consistent performance is key to long-term satisfaction.

Enhanced Air Removal Efficiency

Because of their design, chamber sealers excel at removing air more thoroughly than other sealing methods, which considerably extends the freshness and shelf life of your food and bulk products. This efficiency is driven by advanced vacuum technology that effectively evacuates air from the entire chamber, ensuring a uniform seal. Packaging innovations in chamber sealers allow for stronger, more consistent vacuum pulls, minimizing the risk of air pockets. As a result, your items stay fresh longer, and spoilage is slowed. Unlike external vacuum systems, chamber sealers remove air in a single, contained environment, reducing contamination risks. This enhanced air removal efficiency makes chamber sealers ideal for preserving delicate foods, liquids, and large quantities, giving you a reliable, professional-level packaging solution. Heat distribution in chamber sealers is carefully controlled, further improving the consistency and quality of the seal. Additionally, their ability to handle bulk packaging efficiently makes them a preferred choice for commercial use.

Superior Seal Strength

The strong, consistent seals created by chamber sealers are a key advantage for anyone looking to preserve food and bulk products effectively. Superior seal strength guarantees your packages stay airtight, preventing spoilage and freezer burn. This reliability comes from mastering sealing techniques that rely on precise temperature and pressure control within the chamber. Regular equipment maintenance is essential to maintain this seal quality; clean seals prevent leaks and ensure longevity. Unlike external sealers, chamber models provide uniform heat distribution, resulting in stronger, more durable seals. Consistent sealing performance is achieved through advanced control systems that monitor and adjust sealing parameters in real-time. With proper care and attention to sealing techniques, you can trust your chamber sealer to deliver consistent, high-strength seals that protect your products during storage and transport.

How Do Chamber Sealers Work? The Technology Explained

Chamber sealers work by removing air from the entire chamber, creating a vacuum that helps maintain your items. Then, heat is applied to the sealing bar, melting the plastic and forming a tight seal. This combination of vacuum and heat ensures your packages stay fresh and secure.

Sealing Process Mechanics

To understand how chamber sealers work, it’s important to recognize that they create a vacuum environment inside the chamber before sealing the bag. Once the chamber is sealed and the air is removed, the machine uses a heated sealing bar to fuse the packaging materials together, forming an airtight seal. This process guarantees that the vacuum is maintained, preventing air from re-entering the bag. The choice of packaging materials is vital, as they must be compatible with the heat sealer to ensure a strong, lasting seal. Proper maintenance tips, like keeping the sealing bar clean and inspecting the gasket regularly, help guarantee consistent performance. Additionally, filtration and pump protection are crucial for maintaining the efficiency and longevity of chamber sealers. Understanding these mechanics allows you to maximize your chamber sealer’s efficiency and extend its lifespan, especially since proper maintenance can prevent common issues and ensure optimal operation over time. Regularly monitoring vacuum pump performance and ensuring that all components are in good condition will further improve sealing results and equipment durability. Incorporating adequate ventilation can also help prevent overheating and prolong the lifespan of your equipment. Proper care of these systems ensures consistent sealing quality and prolongs the lifespan of your investment.

Vacuum and Heat Application

Vacuum and heat application are at the core of how chamber sealers create airtight packages. You use vacuum technology to remove air from the chamber, creating a low-pressure environment that prevents spoilage and freezer burn. Once the air is evacuated, heat sealing comes into play. The heat sealing element melts the plastic film, forming a secure, airtight seal. This process guarantees that the bag’s contents are protected from outside contaminants and oxygen. Unlike external sealers, chamber sealers integrate vacuum and sealing within the same chamber, enabling the vacuum to be applied before heat sealing. This simultaneous operation ensures consistent, high-quality seals every time, making chamber sealers ideal for preserving food, pharmaceuticals, or sensitive items. Understanding the technology behind these sealers highlights their efficiency and reliability in various applications.

How to Choose the Best Chamber Sealer for Your Kitchen or Business

Choosing the right chamber sealer depends on understanding your specific needs and the volume of packaging you plan to do. If you handle large quantities regularly, look for models that offer advanced packaging automation features to streamline your workflow. Consider sealing customization options, such as adjustable seal times and temperatures, to guarantee optimal results for various products. Think about the size of your operation—larger units with bigger chamber capacities are better for businesses, while smaller ones suit home kitchens. Also, evaluate how the sealer integrates with your existing setup and whether it offers user-friendly controls. By aligning these features with your needs, you’ll select a chamber sealer that enhances efficiency, maintains consistent quality, and supports your packaging goals. Additionally, choosing a model with simple maintenance requirements can help ensure your equipment remains reliable over time.

Common Uses of Chamber Sealers at Home and for Small Businesses

Chamber sealers are versatile tools that fit well into both home kitchens and small business operations. You’ll find them perfect for preserving bulk foods, sous-vide cooking, and packaging fragile items securely. They work well with various packaging materials, ensuring airtight seals every time. Proper maintenance tips, such as cleaning the seal bar and replacing worn gaskets, help prolong their lifespan. Regularly inspecting and maintaining sealing surfaces is crucial for consistent performance. Additionally, understanding the different types of vacuum sealers available can help you choose the best model for your needs. Recognizing the benefits of chamber sealing can lead to more reliable and longer-lasting packaging results. Here’s a quick overview of common uses:

| Application | Packaging Material | Maintenance Tips |

|---|---|---|

| Food preservation | Vacuum bags, pouches | Clean seal bar regularly |

| Sous-vide cooking | Special heat-safe bags | Check gasket integrity |

| Small product packaging | Heavy-duty film | Replace worn parts |

| Bulk storage | Heavy-duty vacuum bags | Lubricate moving parts |

| Fragile item packaging | Resealable vacuum pouches | Inspect sealing surfaces |

A helpful tip for maintaining optimal performance is to regularly inspect and clean all sealing components to prevent buildup and ensure airtight seals.

Are Chamber Sealers Worth It? Pros and Cons You Should Know

If you’re considering investing in a chamber sealer, it’s important to weigh their advantages and drawbacks carefully. These sealers excel at vacuum packaging large quantities or delicate items, offering consistent, professional results with advanced sealing techniques. They often provide faster sealing, better preservation, and less risk of puncture damage compared to external sealers. Additionally, chamber sealers typically have affordable maintenance, ensuring they remain effective over time. They also utilize advanced sealing technology to achieve superior airtightness. However, chamber sealers usually come with a higher price point and take up more space, making them less practical for casual users. Maintenance can also be more demanding. If you frequently vacuum package bulk items or want the highest quality seals, a chamber sealer is worth it. But if you only vacuum seal occasionally or have limited space, a simpler external model might suit you better.

Frequently Asked Questions

Can Chamber Sealers Be Used for Liquids or Wet Foods?

Yes, chamber sealers are ideal for liquid sealing and wet food preservation. Unlike external vacuum sealers, they handle liquids without leaking, thanks to their design that allows the bag to be inside the chamber during sealing. You can seal soups, stews, or marinated items securely, preventing spills and ensuring freshness. This makes chamber sealers perfect for preserving liquids and wet foods easily and efficiently.

How Long Do Chamber Sealer Bags Typically Last?

Chamber sealer bags typically last between 1 to 3 years, depending on usage and storage conditions. You can maximize their durability by storing them in a cool, dry place away from direct sunlight. Proper handling and avoiding sharp objects help maintain bag integrity. Keep in mind, high-quality bags tend to have a longer storage lifespan and better resistance to punctures, ensuring your food stays fresh and well-protected over time.

Are Chamber Sealers Suitable for Sous-Vide Cooking?

Like a modern-day Mary Poppins with a magic bag, chamber sealers are excellent for sous-vide cooking. They handle liquid sealing and wet food with ease, ensuring a tight, leak-proof seal. This makes them perfect for sous-vide, where maintaining precise temperature and preventing water from entering the bag is vital. You’ll find chamber sealers reliable and efficient, giving you professional results every time without the hassle of leaks or broken seals.

What Maintenance Is Required to Keep a Chamber Sealer in Top Condition?

To keep your chamber sealer in top condition, you should regularly perform cleaning cycles to prevent residue buildup. Check and maintain the seal strip by cleaning it with a damp cloth and inspecting for wear or cracks. Properly lubricate moving parts as recommended by the manufacturer, and ensure the vacuum chamber stays dry and free of debris. Consistent maintenance will extend your sealer’s lifespan and guarantee reliable sealing performance.

Are Chamber Sealers Energy-Efficient Compared to External Models?

Chamber sealers are generally more energy-efficient than external models because they use less power during operation and heat up faster. You’ll find that their design reduces energy wastage, making them a cost-effective choice in the long run. When comparing costs, think of the energy savings over time, which can offset the higher initial investment. Overall, chamber sealers provide better energy efficiency and can be more economical for frequent use.

Conclusion

While chamber sealers may seem like a luxury, they’re really an investment in freshness and efficiency. Sure, external models are cheaper and simpler, but they can’t match the durability and quality of chamber sealers. Think of it like choosing between a quick fix and a long-term solution—you’ll appreciate the superior sealing and versatility when it counts. Ultimately, if you want professional results at home or business, chamber sealers are worth the extra step.